The precision of our

Spin galvanized protection

Spin galvanizing is a hot-dip method with small steel components (less than 3kg) as its target, including nuts, bolts, washers, clamps, anchors, elbows, fittings, and base plates.

Following robotic immersion of molten zinc, components are moved to a perforated spin basket and rotated at high RPM to elute the excess zinc- leaving a smooth and uniform coating and clean and thread-safe surfaces that match the requirements of ASTM A123 / A153.

Contact us

Why is this process better?

The process offers better protection, exact thickness of coating, and finishes - ideal in small, precise parts that operate in harsh environments.

Uniform Zinc finish

Even coating with no bridging, runs, or “icicles"

Thread-safe protection

Spin-off clears threads and mating faces; not re-tapping as much.

Fewer rejects

Fewer rejects.

Consistent thickness

Controlled window of processes provides reliable coating (µm) reports available.

Eco-efficient

Optimal zinc use and energy, reduced waste minimized, aligned with Vision 2030.

Fast throughput

Basket batches and automation allow rapid scale turnaround.

Spin Galvanized System Process

Follow each step of our Spin galvanizing workflow as you scroll.

Inbound & Batch Registration

Each batch is received, sorted and digitally registered. Process requirements are checked to surface condition to ensure complete traceability.

Shot Blasting

Mechanical cleaning with sand blasting in order to remove rust, oil or old coating to provide a reactive steel surface to enable a metallurgical bond.

Degreasing

Oil and grease are removed in a special alkaline greasing bath and this will guarantee that no contaminants will be used to tamper with the quality of zinc bonding.

Rinsing & Pickling

Rinsing and taking the place of oxides and mill scale with acid pickling are done comprehensively to develop an ideal surface on which a zinc-iron alloy layer can be formed.

Fluxing

Flux solution averts re-oxidation and encourages wetting to ensure that molten zinc moves evenly across all surfaces during hot-dip.

Drying

Controlled drying removes moisture before dipping, reducing zinc spatter and surface defects while ensuring stable immersion and better zinc bonding for a clean, even and uniform coating finish.

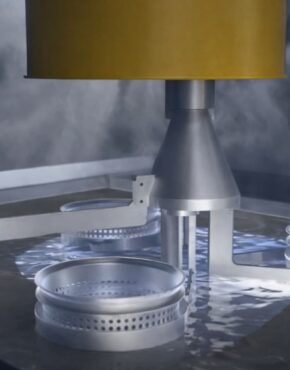

Hot Dip Galvanizing

Components are dipped in molten zinc at about ~445–455 °C. Zinc bonds metallurgically to steel to form a patina of zinc-iron alloys giving the steel corrosive resistance.

Centrifuge & Cooling

Immediately after the withdrawal, components are inserted into a perforated basket, and rotated at a process controlled RPM to remove the extraneous zinc on threads, edges and recesses. Stabilization of the coating is achieved through cooling.

Passivation

Optional passivation bath improves surface appearance and provides an extra layer of protection against early oxidation.

Packaging & Quality Control

We check coating thickness (µm), bonding, and visual consistency. We offer batch reports and third party tests on request. The parts are then packed and labeled and shipped.

Borak Mehnur

City Center

Court Imperial

Key Features of Spin Galvanized Coating

Designed for small threaded and detailed steel parts where uniform coverage, precision, and assembly-ready threads are critical.

Uninterrupted, Flat Finish

Smooth, drip-free coating ideal for small threaded and detailed steel parts.

Precision Application

Controlled coating that protects parts without affecting dimensions or tolerances.

Excellent Adhesion

Metallurgically bonded zinc layer delivers strong, long-lasting attachment to steel.

Thickness Control

Uniform, controlled coating thickness across all surfaces, including edges and recesses.

Thread-Safe Coating

Keeps threads clean and functional, so fasteners are assembly-ready with no rework.

Eco-Efficient Operation

Optimized zinc usage and lower energy consumption to reduce waste and improve sustainability.

Start your Project Today - With Precise Protection Through Spin Technology

Technical Specifications

Controlled Spin galvanizing parameters for consistent, long-life protection.

| Parameter | Specification |

|---|---|

| Coating Material | Zinc (≥99.995% purity) |

| Typical Coating Thickness | 40–85 µm (customizable per specification) |

| Temperature Control | 445°C – 455°C |

| Centrifuge Speed | 500–1,500 RPM (depending on part size and weight) |

| Adhesion Test | Compliant with ASTM A123 / A153 |

| Corrosion testing | Salt spray (ASTM B117) on request |

| Surface Finish | Smooth, uniform, thread-safe |

| Environmental Standard | ISO 14001 aligned practices, low zinc waste system |

Key Benefits of Spin Galvanized

High-performance protection for fasteners and fittings—engineered for durability, speed, and cost efficiency.

Improved Corrosion Resistance

Protection over the long term even in extreme conditions.

Longer Component Life

Prolongs the life of bolts, nuts and fittings.

Better Productivity

Fast response time — between 24 and 48 hours.

Economical

Reduced maintenance and replacement expenditure.

Green

Low waste, sustainable operation without maximum zinc loss.

International Standard Compliance

ASTM, ISO and EN galvanizing standards meet.

Comparison between Spin Galvanized & Traditional Galvanized

A practical comparison of coating method, finish, accuracy, and suitability for different steel component types.

Method

The molten zinc is dipped on small pieces which are then rotated in high speed to shed off excess zinc.

Metal is dipped into molten zinc and allowed to drain itself.

Best For

Ideal Small, threaded, or complex parts (nuts, bolts, washers, fittings).

Massive edifices such as beams, pipes, sheets and fabricated assemblies.

Post - treatment

Post-treatment spinning is used to obtain even distribution and avoid sticking or clumping.

Draining may result in uneven surfaces or zinc deposits on complicated components.

Surface Finish

Surface Finish Smooth, even, no drips or runs - precision components.

May contain thousands of coats; fine parts not permitted; but structural steel is.

Thread Accuracy

Threads are clean and useful because of extra zinc removal.

Threads should also be re-tapped or wiped off.

Thickness Control

Thickness Control Very uniform and steady.

The thickness of coating depends on shape, and angle of immersion.

Corrosion Resistance

Corrosion Resistance Superior, since there is no spot of difference on small surfaces.

Very good, particularly as an exterior or building finish.

Durability

Durability: Small components in harsh environments are high in terms of durability.

Ranges High in large portions, appropriate to long-term exposure.

Processing Speed

Speed Processing Speed Faster on small parts; basket-based batch processing.

slower in many ways; more steps to do.

Automation Potential

Automation Potential Small parts can easily be automated or semi-automated

Another thing is more manual loading/unloading of large items.

Applications

Nuts, bolts, washers, screws, brackets and fittings.

Beams, guardrails, pipes, fencing, structural frames, towers, and so on.